Characterization and Modeling of Thixotropic Elasto-Visco-Plastic (TEVP) Materials

Michela Geri

Thixotropic Elasto-Visco-Plastic (TEVP) materials are substances that display a combination of viscoelastic behavior at small deformations, while flowing plastically at large deformations above a stress threshold known as yield stress. The adjective thixotropic refers to the time evolution of the plastic properties due to their dependence on the shear history experienced by the material. The majority of substances that we use directly or indirectly on a daily basis, such as foodstuff, consumer products, pharmaceuticals, coatings, inks, paints, biofluids and biomaterials, just to name a few, fall into this broad category of TEVP materials.

Waxy oils and clathrate hydrates

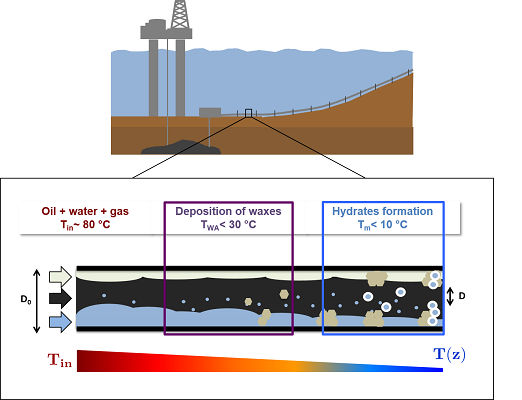

In collaboration with Chevron ETC we are investigating the behavior of two specific types of TEVP materials: waxy crude oils and clathrate hydrates. In deepwater fields, as the oil is extracted from the well and cooled down by the surrounding water, paraffin waxes and hydrates start to appear as solid particles, changing the mechanical response of the oil and posing a serious risk to the operability of the pipelines (Figure 1). Our goal is to characterize the rheological behavior of crude oils when waxes or hydrates are present, and to model such response with appropriate and consistent constitutive equations.

Figure 1. As oil cools down after extraction, paraffin waxes and hydrates appear as solid particles, changing its rheology.

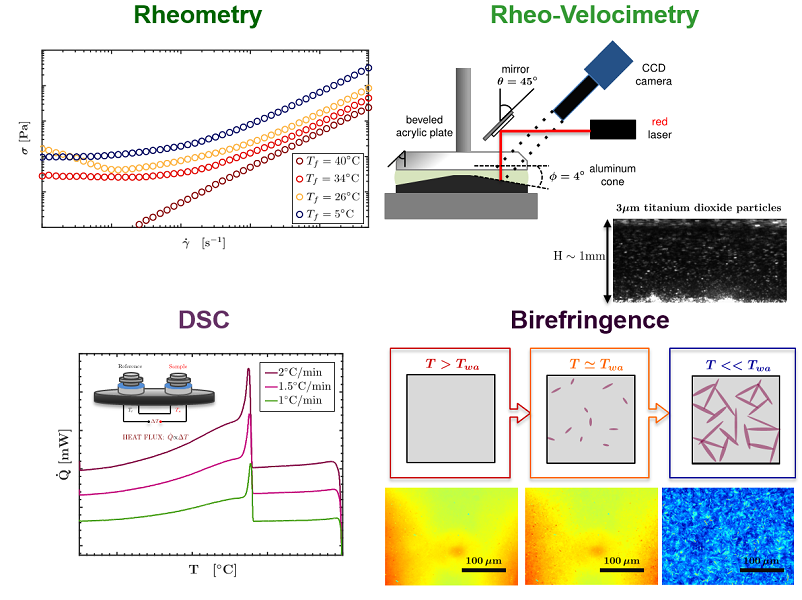

To fully characterize the behavior of both model and real crude oils we use different techniques, which include rheometry and rheo-velocimetry in order to monitor the local velocity field while performing rheometric measurements, thermo-analytical DSC measurements to understand and quantify the phase transitions that happen when solidification occurs, and microscopy, especially birefringence and polarized light, to directly look at the microstructure (Figure 2). By combining all these techniques, we have been able to improve our understanding of waxy crude oils, and develop a constitutive framework that captures many important features of their plastic behavior such as temperature dependence and thixotropy (Figure 3).

Figure 2. A combination of different methods is used to investigate the behaviour of crude oil.

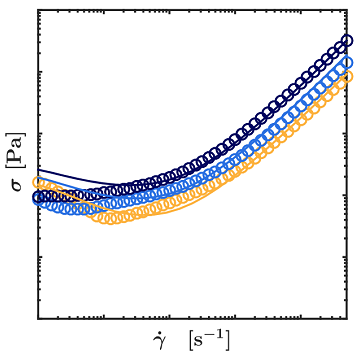

Together with our collaborators at ENS Lyon (Prof. Sébastien Manneville and Dr. Brice Saint-Michel) and at CNRS Bordeaux (Dr. Thibaut Divoux) we are currently investigating what happens at small shear rates where waxy crude oils exhibit a region of decreasing stress with increasing shear rate. This characteristic is encountered in many complex fluids and it is associated with the presence of different instabilities in the flow field. By combining rheometry with local USV (Ultrasound Speckle Velocimetry) measurements, we are now looking at the response of these particular materials to understand if the non-monotonic behavior is a true characteristic or if it is a consequence of a complex flow field.

Figure 3. Rheological response of waxy crude oil.

Material characterization via innovative experimental and numerical methods

Standard techniques used to characterize complex fluids are often limited by the fact that they can probe only a limited number of material properties at a time. For many real materials this may be an important issue given their complex rheological response. We are therefore interested in developing new experimental techniques to improve our ability to test complex fluids as well as innovative data processing methods that have the potential to be effectively used for any material.